The theory of six sigma was first used and developed at organizational level in 1986 by an engineer ‘William Bill Smith Jr.’ of Motorola, an American Multinational Telecommunications Company. The aim of Bill was to devise a mechanism that would standardize the defect management system in the manufacturing process of Motorola. In result, Motorola formulated such a method that provided them with a metrics to improve and monitor their quality development. The six sigma was reflective based on the metric that a product or process will only have 3.4 defects in a million opportunities. To begin with, implementing Six Sigma spreads a progressive process improvement methodology to all organization levels. Since Six Sigma helps reduce the defects and flaws in the products, the focus on failure reduces.

Disadvantages of Six Sigma

Besides above two methods, other notable tools for applying six sigma are DOE (Design of Experiments), FMEA (Failure Mode Effects Analysis), Pugh Matrix (Decision Matrix Method) etc. Six Sigma, being a methodical and structured approach, might not always be quick to adapt to sudden market shifts or unexpected challenges. Companies solely relying on it might find themselves lagging, especially when rapid decision-making is required.

Lean vs Six Sigma: The Most Important Differences and Similarities

Organizations can measure the success of their Six Sigma initiatives through various metrics, including defect reduction, process cycle time improvement, cost savings, and customer satisfaction levels. By identifying the causes of variations and eliminating waste in production processes, Lean Six Sigma makes operations more predictable, reliable, and efficient. With Six Sigma implementation in manufacturing, the revenue to the business increases as part of the quality.

Six Sigma Certification and Belt Rankings

Organisations can differentiate themselves from competitors by consistently delivering high-quality products and services. This competitive advantage can attract new customers, retain how to convert a money factor to an interest rate existing ones, and open up opportunities for business growth. Writer and editorial manager for about 15 years, Adeline is passionate about human behavior and communication dynamics.

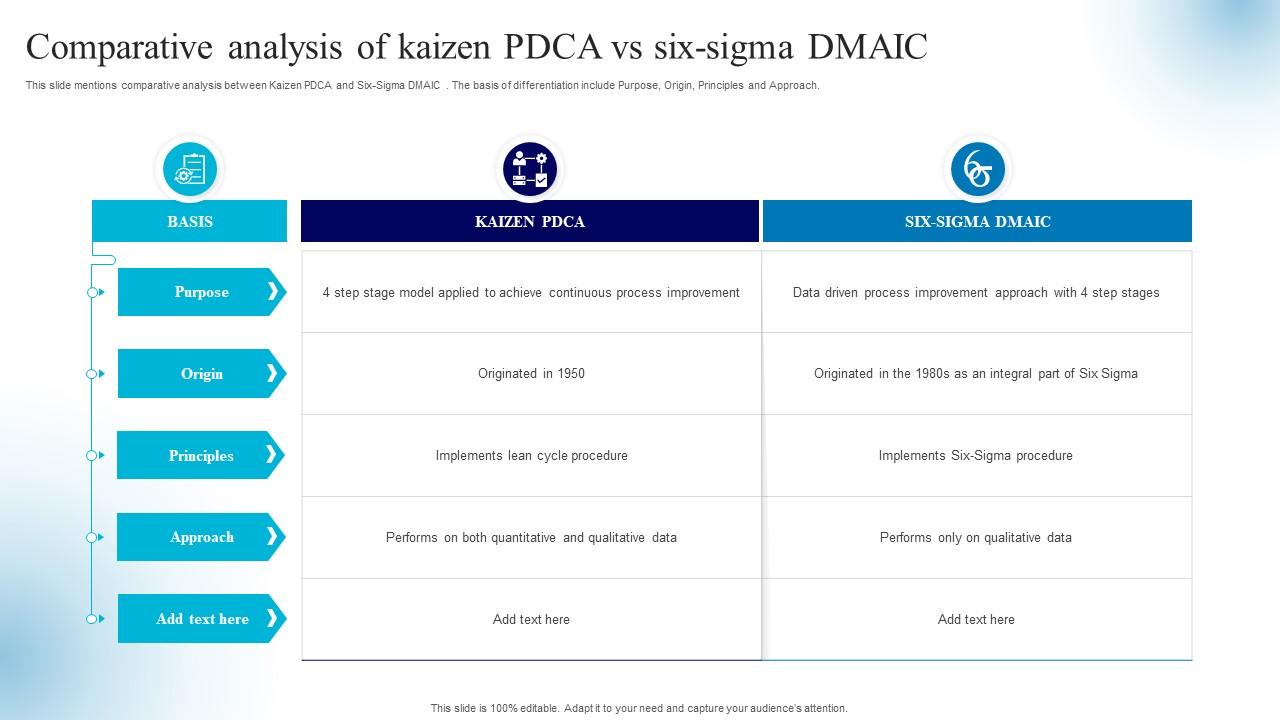

Different Approaches

- They both help in augmenting the quality of a product, which in turn helps to satisfy the customer.

- With Six Sigma implementation in manufacturing, the revenue to the business increases as part of the quality.

- In the improvement stage of DMAIC Six Sigma, you begin to map out solutions and the actions to take.

- With time, progressive quality improvement may lead to increased overhead and capital costs due, thus canceling out initial savings made.

- Reducing waste, defects, and inefficiencies in processes enables companies to make significant savings, especially in operational costs.

Implementing Six Sigma leads to a significant improvement in the quality of products and services. Organisations can consistently meet or exceed customer expectations by identifying and eliminating defects. This focus on quality enhances customer satisfaction and helps build a strong reputation for the organisation. Six Sigma is also a set of tools and techniques that organizations use to improve business processes. This data-driven process works with six standard deviations between the mean and the closest specification limit.

Focus on Process Improvement

It helps in reducing the costs initially after identifying and fixing the problems. Through Six Sigma methodologies, companies can upgrade and improve quality control. This positively impacts the quality of products and consequently enhances customer satisfaction and brand loyalty. Lean also has roots in software development, where it helped optimize the software development life cycle of Agile methodology. It creates value for the customer by optimizing a company’s resources, effort, and energy. Use the Lean methodology to identify the root cause of waste, reduce waste, deliver value, and improve the production process.

When Six Sigma incorporates into production processes, product complaints will decrease. Six Sigma methodology is primarily developed for the manufacturing industry, where faults or defects are the main problems. In the production of a particular number, certain tolerances are acceptable. Six Sigma helps reduce this number by identifying the core defects in the production and suggesting ways to overcome them. In addition, it explains the defects as the exceptions from the customer requirements.

They both help in augmenting the quality of a product, which in turn helps to satisfy the customer. Six Sigma has a hierarchy of certifications ascending from White Belt, to Yellow Belt, to Green Belt, and finally to Black Belt and Master Black Belt. Someone with the Six Sigma certificate in Master Black Belt can become a project manager who consults on projects and offers strategic guidance to organizations. The rigid structure of Six Sigma, while excellent for efficiency, might stifle the creative process.